Capacity: From 500 kg/h to 2.000 kg/h

Model: 200 – 1100 – one separate Rotary Knife Unit

200 – 550 – two separate Rotary Knife Units

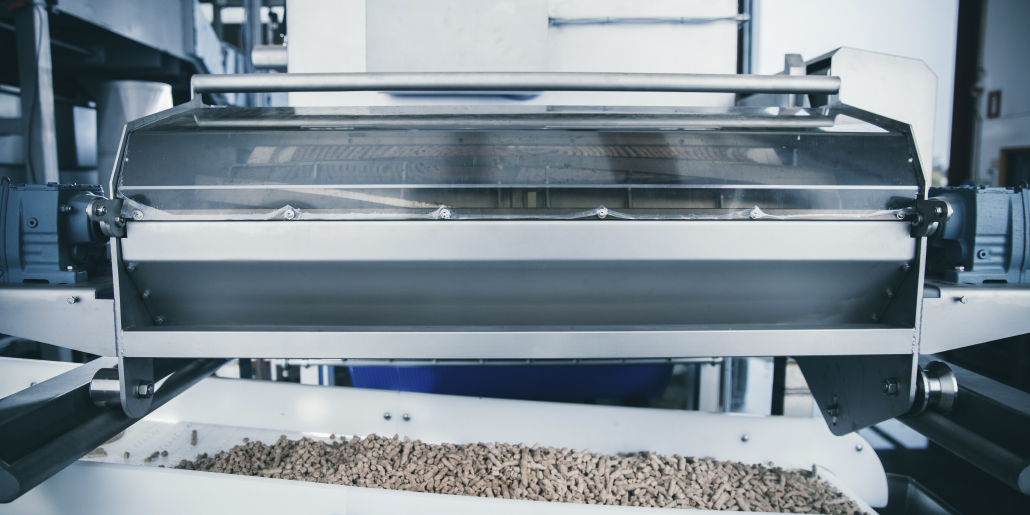

The “ROTORCUT” machines includes:

- One Rotary Knife on one shaft designed with twisted cutting knife – 45 degree – length 1.100 mm alternatively

- One Rotary Knife on two shafts (built together) designed with two twisted cutting knives, each 45 degre

- Length 550 mm

- One or Two gearmotor driving units depending of ROTORCUT Type connected to frequency inverters

- Possible to process complete different variable dimensions ( from 5 to 60 mm)

meat “Chunks” simultaneously via oscillating Microprocessor operated frequency inverters. - Transmission of cutting cylinders by Poly-chain Toothed belting

- “ROTORCUT” machine equipped with sliding/wheel for removal into cleaning position – outside cooling belt area. Due to this very easy disassembly and sanitation of machines

Automatic:

Complete programable push-button keyboard to microprocessor with digital Display. Integrated mechanical as well as electrical SAFETY system of the “ROTORCUT” Machines.

Operation of the “ROTORCUT” machines by one Menu programable Microprocessor by attached Touch Screen including Memory for storing of Data and various previously programmed Menus.

Finish:

“ROTORCUT” machines are manufactured complete in stainless steel and/or food approved plastic – Components