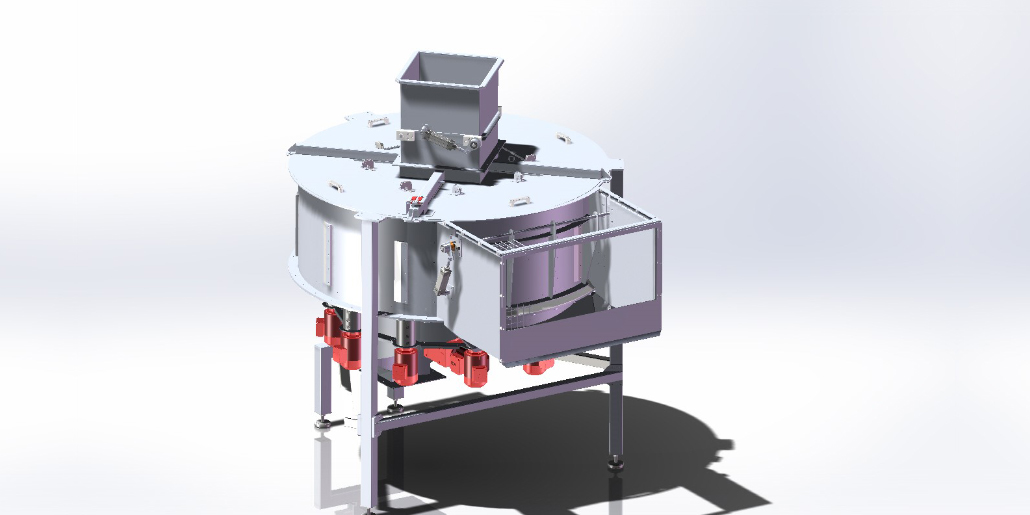

To archive the looking of a manually knife peeled product with smooth surface resulting in maximal shelf life with nice looking product we have developed the Rotary knife Peeler.

Function:

The system is operating a batch of product at the time. The batch volume depends of the product – by typically 60 kg/batch.

A bottom plate is rotating around a vertical cylinder to bring the product into rotation.

Further the bottom plate is equipped with 8 separate rotating knife-disc’s, each easy height adjustable to control the peeling efficiency (yield).

The tumbling of the product inside the drum by means of the rotary bottom ensures that all the product will be peeled gently and evenly.

After peeling the product is discharged through a pneumatical/mechanical operated door at the side of the peeling cylinder.

Infeed from the top is to follow immediately after discharging.

Dimension:

Diameter: 1.700 mm

Infeed Height: 2.400 mm

Discharge Height: 1.200 mm

Efficiency:

Due to operation the bottom plate and the separately rotary cutting disc´s the product is tumbled very effectively thus giving a very good capacity. To keep the rotary disc’s free from peels a little water is added continuously.

Capacity:

Up to 1.800 kg/h by potatoes and 1.600 kg/h carrots.

Equipment:

The machine is manufactured complete of stainless steel and is equipped with:

- Infeed funnel.

- Water Inlet pipe/distributor with magnet valve for factory water.

- Discharge Gate – electro/pneumatic operated.

Option:

By connecting of frequency inverters it is possible to have the separate rotating bottom plate as well as the 8 rotary dishes to operate with different speeds depending on product.

The machine is made in 3 different dimensions – one for lower capacity and one for higher capacity.