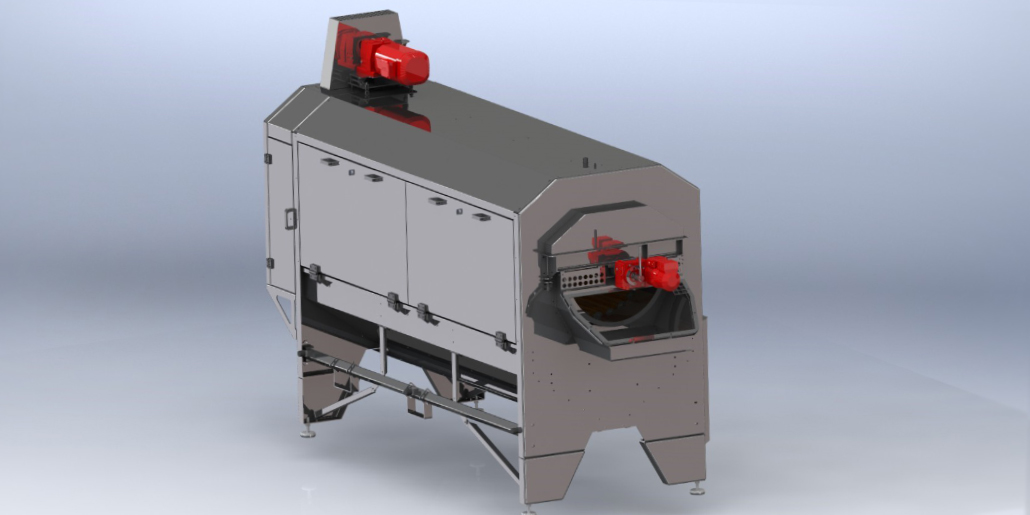

The Master Peeler is manufactured of stainless steel with 24 rotary rollers built into a round rotary shaped frame with one central screw placed inside the rotary drum.

The screw is for controlling the time inside the peeling drum. This takes place by using a frequency inverter connected to the gear drive of the screw.

All rotary abrasive rollers can be exchanged very fast due to special bayonet connection system. Each roller is equipped with a V-belt drive wheel in order to adjust the speed for all the abrasive peeling rollers by means of a separate frequency inverter.

All the abrasive rollers are placed into round rotary frame, thus framing/forming all rollers as a drum with sprocket operated chain drive operation, and with a large screw placed in the middle for control of peel-time.

Dimensions of master peeler:

Length: 4.100 mm

Width: 1.100 mm

Height: 2.400 mm (incl. gearmotor on top of machine)

Infeed Height: 1400/1700 mm

Discharge Height: 700/1700 mm

The efficiency:

The efficiency of the MASTER Abrasive Peeler is due to the fact that 3 (three) parts are rotating:

- All 24 abrasive rollers are ROTATING

- The total Drum of all rollers is ROTATING

- The Screw in the middle of the Drum is Rotating

And all 3 (three) parts are individually speed/rotation adjustable by means of frequency inverters.

This unit triple rotating makes the peeling very efficient due to the fact that the product is constantly in motion, thus tumbling down at another.

Drum:

The total Drum is covered be a very HEAVY DUTY Frame with covers along each side, which can be opened manually for inspection/cleaning.

For collection of the peel waste/offal the machine is equipped with V-angled collection funnel down to a long opening for drain to below placed canal or alternatively it can be equipped (against extra costs) with a long separate waste screw discharging at one end.

Equipment:

The machine is equipped with magnetic operating valve for flushing plastic bearings automatically.

The machine is delivered with one Electrical Panel including necessary safety-relays as well as all internally cabling/wiring of the Frequency inverters and sensors.

Option:

Some customers are using a number of nylon brush rollers mixed into the abrasive rollers.

This brush rollers with relative “stiff” blue plastic brush hair will help to “rip” off the peel, thus getting the abrasive rollers to operate/peel even better.

We could suggest to equip the Master Peeler with up to 5 (five) Brush Rollers placed strategically into the other rollers.