The system is operating continuously with separation of natural stones from vegetables/roots ensuring no damaging of following equipment like washers, peelers and slicer/dicers.

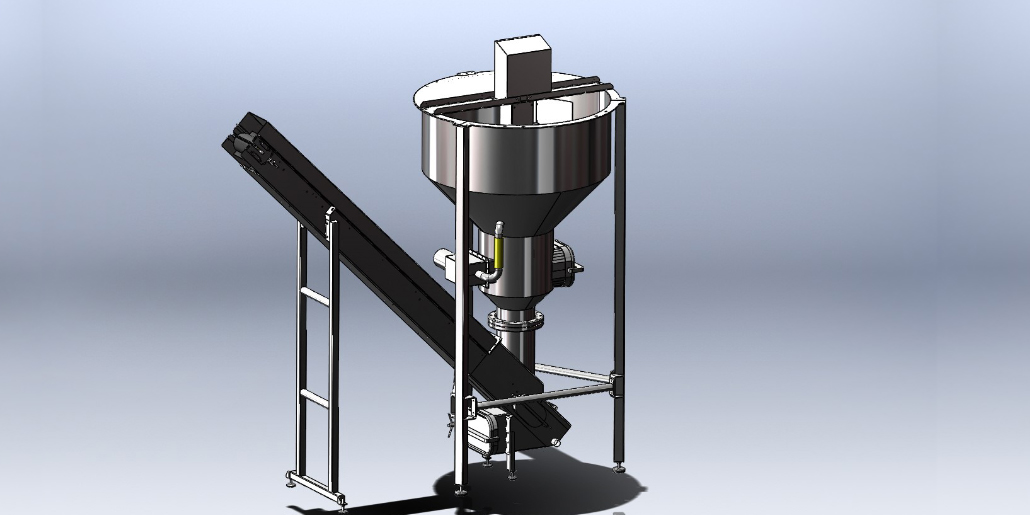

The system uses the flow ability of the product to separate natural stone / soil from product. A rotary propel is bringing the water into a cyclone circulation, which separate the heavier natural stones, gravel and soil from the product.

The product is slipped over a lower edge of the conical water vessel/tank. Stone, sand/soil can be removed manually through a large trap/door after operation or alternatively can be removed continuously by means of a built in elevator into the conical water vessel/tank.

The overflow water together with de-stoned/pre-washed products is separated by a grill, leading the water back into the conical water vessel by gravity and by a robust pump injecting part of the water into the bottom of the vessel thus forming a water-flow lifting the product up/over the lower edge of the tank and to the next machine for further processing. The water is recirculated all the time – only a little “make-up” water is continuously added.

Model/Type:

| Model/Type: | 2200 DS Automatic | 2200 DS Manual | 2600 DS Manual | 2600 DS Automatic |

| Diameter: | 2.200 mm | 2.200 mm | 2.600 mm | 2.600 mm |

| Height: | 2.400 mm | 2.400 mm | 2.400 mm | 2.400 mm |

| Discharge Height: | 2.000 mm | 2.000 mm | 2.000 mm | 2.000 mm |

| Conical Buffer tank: | 2.0 m3 | 2,0 m3 | 2,5 m/3 | 2,5 m3 |

Capacity:

From 6.000 kg/h up to 25.000 kg/h depending on root diameter.

Equipment:

- The total machine conical water buffer vessel/tank and parts are manufactured either in stainless steel or in food prof plastic material.

- The machine is designed with an overhead vertical placed shaft connected to one gearmotor for rotating of propel to keep the water and product in circulation with a controlled overflow of water/product mix into the following machine.

- By conical buffer water tank equipped with stone/sand removal elevator the elevator is manufactured with frame of stainless steel and belt of heavy duty rubber quality with rib-driving- and idle drums of stainless steel.

- Conical Water Buffer-Tank is equipped with a 500 mm cut out overflow section for product/water mix discharge leading into a stainless steel grill for dewatering of product before dropped into the next machine.

- Further the conical water buffer tank is equipped with a draining valve and large cleaning trap/door.

Drive:

- One gearmotor placed at the top of the vertical shaft connected to the rotary propeller by means of a chain drive system.

- Motor can be connected to a frequency inverter for change of screw speed against extra cost.