VACUUM TRANSPORT SYSTEM

Transporting a product by vacuum or air has been used for many years.

But by using electronic microprocessor flow control for the vacuum transport system has pushed the way of transporting/transferring many products today.

DANA-Technology has been involved in this industry for now many years by installing Vacuum Transport Systems for the final product to be packed into bags, cans, trays or cartons.

Today it is not only powder or waste materials to be vacuum transported, but the final end product to be served to the end customer.

Products like frozen IQF vegetables and IQF Seafood are among the many various products to be transported.

The beauty of the system is the possibility of conveying product over longer distances as well as being able to feed the product example from a cold-store area to the position where the product should be filled/packed or used for further processing.

As the system allows the product can be transported vertically and horizontally, it makes it possible to place the pipes below the roof, thus eliminating the problem of crossing existing packing- or processing Lines in a factory.

With today’s request for cleaning of transport systems, it is possible to connect the vacuum transport system to a CIP (cleaning in place) equipment, which will ensure perfect disinfection of the pipe, valves and parts in connection with the product.

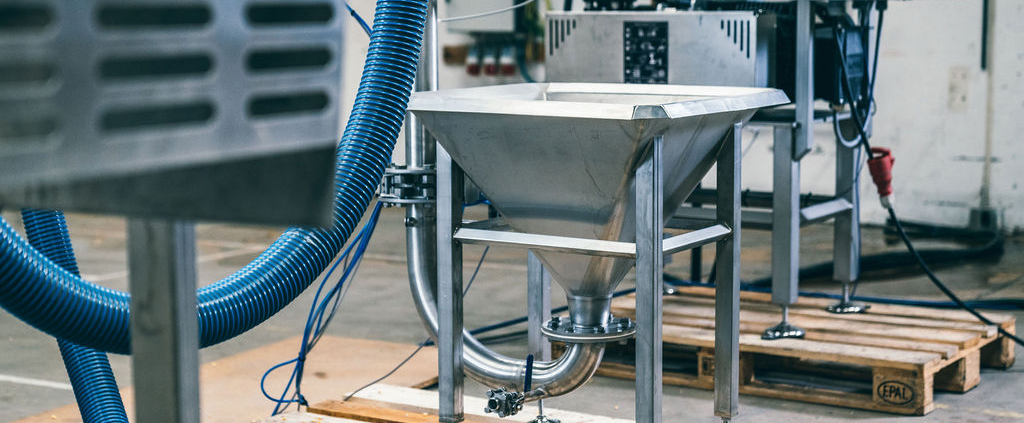

One system can include more suction funnels (for different products) with different pipes and cyclone discharge positions – however, using only one vacuum pump.

Other advantages are the possibility of crossing more rooms on its way to the final destination for discharge.

Let us help you with creating a new way of establishing product transport.

VACUUM TRANSPORT MIGHT BE A GOOD SOLUTION FOR YOUR NEED OF MOVING GOODS.