Samson Pumps is the only company in the world to specialize exclusively in liquid ring vacuum pumps.

For over 40 years, Samson has been synonymous with the strongest pumps and have constantly adapted products to meet the changing needs of customers. Today, it is not enough to simply produce a pump. Products must be refined so the customer can concentrate on what they do best. Dana-Technology offer a wide range of standardized components that allow customers to have vacuum systems build in without the need for specialist in-house.

Strength and durability are the hallmarks! Samson pumps are made in Denmark.

Benefits of the Vacuum Conveying Systems:

- Simple and reliable vacuum system

- Low KW consumption

- Uses water as a propellant with up to 90 % re-use

- Low maintenance costs

- Impurities in the pump do not impede its operation

- Requires little space, and low noise levels mean it can be sited in production areas

- A PLC system for vacuum system and pump monitoring and control

- Can replace existing pressurised systems and deliver significant savings

- Samson vacuum conveying systems have been thoroughly tested in offshore industry

- Units available to test customer products for vacuum transport suitability

- Green and environmentally-friendly approach

Why a Liquid Ring Pump:

- No use of oil.

- No noise problems. (80 Decibel)

- No problems with dirt in pump.

- Reuse of 90 % of water, by using liquid service tank.

- Clean energy in clean surroundings.

- Savings of Kilo Watt. Compared to compressed air, savings are very high, and 100 KW can be reduced to 30 KW

- Can be adapted to existing facilities. (Compressors)

- No costs of service every year as for oil pumps.

Other pumps, compared to DANA (Samson) Pumps:

| DANA – PUMPS | ||

| Compressor system | Vane Pumps | Liquid Ring Pumps. |

| High spend of KW | Low spend of KW | Low spend of KW |

| Airflow for up to 2000 m3 | Airflow for up to 800m3 | Airflow for up to 3000m3 |

| Airflow | Airflow and vacuum | Airflow and vacuum |

| 100 Decibel | 110 decibel | 80 decibel |

| Very expensive | Cheap | Quality and cost effective |

| No dirt | No dirt in pump | Tolerate dirt in pump |

| Lots of filters | No filter use | |

| Service every year | 2 x service every year | No service Is needed |

| Life time of 4-5 years | Life time of 8-10 years |

Details:

- Every pump can be identified by the unique serial and type number, which can be traced back to the time of production.

- Every pump is tested for leaks, performance vibrations and energy consumption and can be tested for top performance for a specific application.

- All pumps are made of the strongest materials. Cast iron and stainless steel makes them the strongest in the market.

- Vacuum conveying of waste in slaughtering processes is only one of the many applications for the Samson liquid ring pumps.

- A strong fully welded rotor is the security for a safe and reliable operation of the pump in challenging environments.

- Our vacuum system handles the whole thing, and are extremely reliable, hardy and make the unloading faster and more efficiently.

- The Pumps are sturdy, durable, highly reliable as well as quiet and environmentally friendly.

- No other materials can match the durability, temperature resistance, vibration damping and overall durability as cast iron.

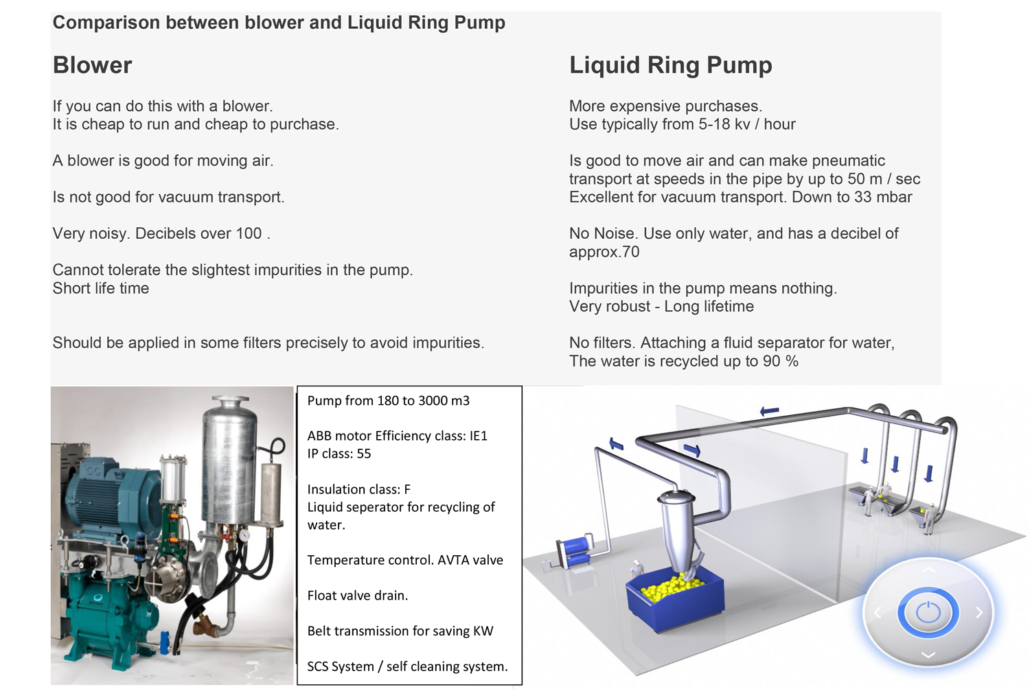

Comparison between blower and Liquid Ring Pump :

Range overview: